More specifically, solid conductor aluminum wiring?

Aluminum wiring was most common in homes built between 1964 and 1976—and of course some electricians used up their stock after 1976. I don’t want to go into a lot of the reasons behind what the problems were, I and others have covered this topic pretty well.

Aluminum Wiring, Can it be Fixed?

Aluminum Wiring–There is Still Lots of it Around

Copper Clad Aluminum

The Aluminum Wiring Hazards & Repairs Website

How serious a problem aluminum wiring is for your home, depends on when the home was built and what has been done to the wiring system since the home was built. By the very early 70’s we became painfully aware of the problems with aluminum wiring as houses started burning down or coming close to burning down.

In 1972 a different grade of aluminum wiring became available, known as the “8000 series aluminum” that eliminated the problems with the earlier “1350 series aluminum.” So to begin with, in discussing the wiring in your home, it becomes necessary to determine which series of wiring you have in your home.

It is my opinion that any house built prior to 1972 that has aluminum wiring, the safest recommendation, is to have the wiring replaced.

If it can be determined that the wiring is the 8000 series aluminum then the options may improve but replacement may still be warranted if a lot of newer copper wiring has been added to the old circuits–especially if non-professional changes have been made.

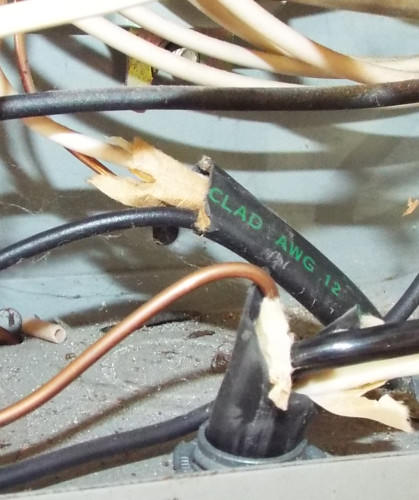

An example of “less than professional behavior” is the following picture.

Every red wire nut represents an improper connection of copper to aluminum—not to mention the connections being made outside of proper junction boxes. In homes with this kind of work, every junction box (switches, lights, etc) should be opened up and evaluated so that repairs can be made as deemed necessary. It should also be verified that all switches and receptacles and other devices are rated for aluminum wiring as well. If receptacles and switches have been “back-stabbed” as opposed to using the side screws that is also something that should be changed in my opinion.

There used to be only one way to make proper connections of aluminum to coppe. The first method was with Copalum connectors which have been long recognized by the CPSC as an approved connector. They require a special tool that only a few contractors have and that are trained to use.

Another connector has arrived on the scene that is also approved, called the AlumiConn connector. This connector is readily available at most electrical supply stores and I suspect will replace the Copalum connector all together due to being very inexpensive.

After all of this is done, you should keep in mind that you will still not have wiring that meets modern standards in that the wire does not have the temperature rating of modern house wiring. This is not a big deal but can be a problem when adding fixtures/devices that are only rated for the higher temperature rated wires. This includes most modern light fixtures.

Having all the circuits protected by modern combination type Arc-Fault circuit breakers is also prudent to add a layer of protection as well. Since these devices are now required on almost all 120 volt circuits in the home, this is a meaningful and worthwhile safety upgrade anyway.

On a case by case basis, each house should have a careful cost/benefit analysis done by the electrician to determine what makes sense for that particular house. On a single story house with a full attic above and open crawl space below, replacement might be the best option. In muti-story homes with finished basements and no attics, replacement might be deemed impractical and some of the other options mentioned above might make more sense.

Keep in mind that any repaired aluminum wiring system is only as strong as the one missed junction box with an improper copper/aluminum splice or device not rated for aluminum.

In the following two pictures we can see where a copper wires (white) has been improperly added to junction box locations.

In the first picture, 3 copper conductor wires (white) have been added to the one aluminum conductor wire (black).

This would not be evident if the attic was not checked, and might never be found if it was buried in insulation. As you can imagine this further complicates evaluation and cost analysis because it may be necessary to remove all the insulation in the attic and crawl space to make better evaluation—to find every location. Even then there will always be the chance that someone has improperly buried a location behind walls or cabinets etc.

In this next picture we can see where one white wire has been added to a box with three black wires.

From the room side, this would not be evident without taking the cover off and checking very carefully.

There is nothing inherently wrong with the 8000 series aluminum, but it can be made unsafe with bad wiring practices.

Solid conductor aluminum wiring will be back as acceptable wiring for residential construction, it is only a matter of time. In fact, it is back already in some larger wire sizes.

By Charles Buell, Real Estate Inspections in Seattle

If you enjoyed this post, and would like to get notices of new posts to my blog, please subscribe via email in the little box to the right. I promise NO spamming of your email!